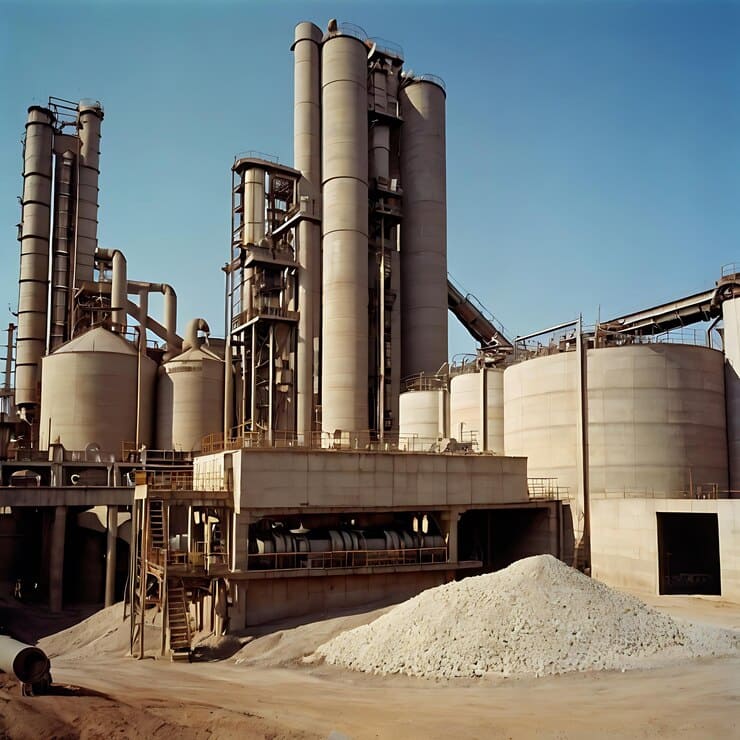

Backed by a team of skilled professionals, we are engaged in manufacturing, exporting and distributing a wide range of fly ash. Skilled professionals at our well-equipped production unit process this ash using quality assured raw materials.

Favored for use in the construction industry, fly ash is mixed with cement to provide additional strength. Moreover, our exported fly ash is distributed to many parts of the world at reasonable prices.

When coal is burned to generate electricity, it is generally pulverized into a fine powder, blown into a boiler, and burned as a fine powder. Any unburnt, passing through, is extinguished and collected as flyash. It is called fly ash because it flies through the boiler. The ash that stays behind is called bottom ash. When the ash is slaked, it remains glassy and is pozzolanic, that is, it reacts with lime to form a cementitious material.

As the ancient Romans used pozzolans in their construction with volcanic ash and lime. Because flyash is a pozzolan, it is a good additive for concrete where it can replace some cement. It can only do that if the flyash is low in unburnt carbon. If the carbon content is high, all you can do is landfill it.

Fly ash concrete offers a distinct architectural benefit with improved textural consistency and sharper detail. Fly Ash is also known as Coal Ash, Pulverized Flue Ash, Pozzolona.

We are supplier of C Grade Fly Ash from Tami Nadu. We can supply it as per customer requirement.

Fly ash produced from the burning of younger lignite or sub-bituminous coal, in addition to having pozzolanic properties, also has some self-cementing properties. In the presence of water, Class C fly ash hardens and gets stronger over time. Class C fly ash generally contains more than 20% lime (CaO). Unlike Class F, self-cementing Class C fly ash does not require an activator. Alkali and sulfate (SO4) contents are generally higher in Class C fly ashes.